Understanding T-Tail Aircraft – Characteristics, Advantages, and Disadvantages

What is a T-Tail Aircraft?

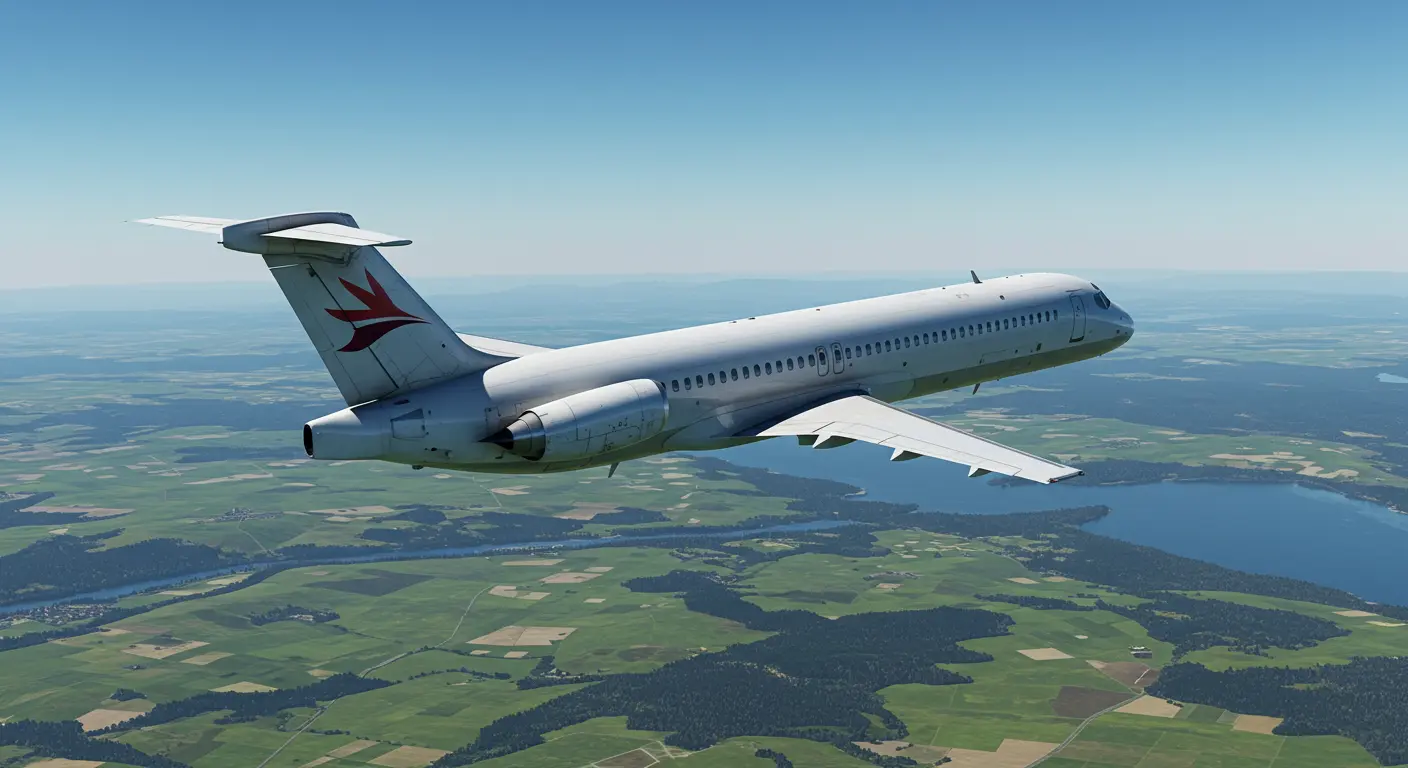

A T-tail aircraft features its horizontal stabilizer (tailplane) mounted on top of the vertical fin, forming a distinctive ‘T’ silhouette. This design departs from conventional configurations where the stabilizer attaches directly to the fuselage.

This arrangement is particularly common on aircraft sporting aft-mounted engines—think McDonnell Douglas MD-82. Why? Positioning the horizontal stabilizer above the chaotic engine exhaust, safeguarding its aerodynamic effectiveness.

T-tails are also prevalent on:

-

High-winged aircraft with engines in nacelles, to keep tail surfaces clear of the jet exhaust.

-

Seaplanes and amphibians, like the Series A-40 Albatross, to keep horizontal surfaces away from water spray during takeoff and landing.

The elevated stabilizer operates in cleaner airflow during normal flight, providing distinct performance benefits and handling characteristics. Yet this advantage comes with a price: unique design complexities and piloting challenges.

Advantages of T-Tail Aircraft

The T-tail configuration offers several compelling aerodynamic and operational advantages that improve performance, handling, and efficiency.

The main advantage is that The horizontal stabilizer operates in pristine air, well above the turbulent wake churned up by wings and fuselage. This translates to more consistent, predictable elevator response for improved control and handling precision.

On aircraft with aft-mounted engines, the T-tail places the stabilizer clear of scorching, turbulent exhaust. This preserves aerodynamic performance while preventing heat damage to control surfaces and maintaining crisp pitch control.

T-tails reduces interference drag between horizontal and vertical stabilizers, improving aerodynamic efficiency—just look at the Tupolev Tu-154. This arrangement also creates an ‘end plate effect,’ increasing the vertical tail’s effectiveness and improving directional stability.

Modern gliders frequently use T-tails for superior performance and enhanced glide ratios. The design improves control effectiveness at low speeds. Additionally, Protection from ground damage and certain spin scenarios.

On cargo workhorses like the Boeing C-17 Globe master, a T-tail creates generous rear clearance, simplifying loading and unloading operations. This design also enhances short-field performance, improving operational flexibility.

At transonic speeds, T-tails provide superior pitch control and can facilitate easier spin recovery compared to many conventional designs.

Stability and Control Benefits

This pristine airstream provides precise pitch control—invaluable during instrument approaches and other precision flying tasks where every degree matters.

Performance in Various Flight Conditions

During low-speed flight phases—approach and landing—the elevated stabilizer maintains pitch authority in undisturbed air. This makes the design particularly attractive for aircraft demanding precise control or short-runway capabilities.

In crosswinds, the tall vertical fin becomes more problematic. The aircraft grows more sensitive to side gusts, demanding specific pilot techniques for safe landings.

Maintenance Challenges

That elevated horizontal stabilizer is difficult to access. Routine inspections, rigging, and lubrication demand special equipment—think tall platforms and specialized lifts. The result? Increased maintenance time and escalating costs.

The vertical fin requires heavy reinforcement to support the stabilizer’s weight, creating numerous critical structural joints and fasteners. These demand rigorous inspection for fatigue and corrosion requiring constant attention.

Control systems become more complex, featuring longer cable runs or hydraulic lines running up to that elevated tail. More components mean more potential failure points including binding and leaks. Precise rigging is more challenging.

The high tail faces greater weather exposure, accelerating wear on surfaces and seals. Ice accumulation in cold climates? This creates additional problems, requiring thorough inspections and meticulous de-icing system maintenance.

These factors collectively drive up operating costs through extended inspection times, specialized equipment requirements, and more frequent component replacements.

Deep Stall Risks

A critical safety concern for T-tail aircraft is the serious risk of deep stall. This occurs when, at high angles of attack, the turbulent wake from stalled wings affects the horizontal stabilizer, rendering the elevator useless and making recovery very difficult.

The deep stall results from T-tail geometry. While that high tail enjoys clean air during normal flight, at steep angles of attack it enters the wing’s chaotic separated airflow. Elevator authority vanishes precisely when recovery demands it most.

Deep stall may be irreversible. The aircraft becomes trapped in a stable, high-angle-of-attack descent with potentially fatal consequences. With the tail continuously shrouded by the wing’s turbulent wake, conventional recovery becomes impossible. This phenomenon has claimed lives, particularly in early T-tail jets.

To mitigate this risk, manufacturers use several methods, and pilots receive specialized training. Design features include:

-

Stick pushers: Automatically push the nose down to prevent the aircraft from reaching a critical angle of attack.

-

Specialized stall warning systems: Calibrated for T-tail flight characteristics.

-

Aerodynamic modifications: Vortex generators or leading-edge devices to improve airflow at high angles of attack.

Military and Commercial Applications

In military transport, the T-tail provides important operational advantages. The Boeing C-17 gets important rear clearance for loading oversized cargo. The Airbus A400M keeps control surfaces effective when operating from rough airfields awash in propeller wash.

Commercial aviation uses T-tails on aircraft with aft-mounted engines—MD-80 series, regional jets, business aircraft. This placement protects the stabilizer from engine exhaust, reducing heat and aerodynamic interference while potentially lowering cabin noise.

Military combat aircraft have used T-tails for specific performance gains. The F-104 Star fighter’s T-tail suited supersonic flight perfectly, while the Blackburn Buccaneer’s configuration supported its demanding low-level strike missions.

These diverse applications demonstrate the T-tail’s versatility. Designers choose this configuration when its advantages in cargo capacity, performance, or comfort match mission requirements.

Conclusion

The T-tail represents a specialized design with clear advantages—improved elevator response and reduced drag—by positioning the horizontal stabilizer in pristine air. This is especially beneficial for aircraft with rear-mounted engines, keeping the tail clear of exhaust interference.

However, the design has a significant weakness: susceptibility to deep stall, where airflow separation from wings can render the elevator powerless. This risk requires mitigation through sophisticated safety systems and specialized pilot training.

The persistent use of T-tails on aircraft ranging from the C-17 Globe master to the MD-82 shows that benefits often outweigh drawbacks for specific missions. Modern designs use advanced flight controls and refined aerodynamics balancing advantages and risks in the intricate engineering trade-offs defining aircraft design.